Enhance your filling with efficient, sustainable, and cost-effective decontamination solutions

Claranor at Pack Expo 2025

Claranor is delighted to announce its participation in PACK EXPO Las Vegas 2025, from September 29th to October 2nd. Come and visit us to explore our Pulsed Light decontamination solutions, proven and sustainable alternatives to chemicals in packaging sterilization.

In collaboration with our partner Primoreels, we will present an efficient and eco-friendly lidding solution.

Why visit Claranor at PACK EXPO 2025 Las Vegas?

At our booth, you’ll learn more about our full range of Pulsed Light equipment, engineered for high-speed filling lines in dairy, beverage, sauces, and plant-based products.

Cup and lid decontamination solution

CUP and LID CHEMICAL FREE DECONTAMINATION: FOR DAIRY, SAUCES, AND MORE

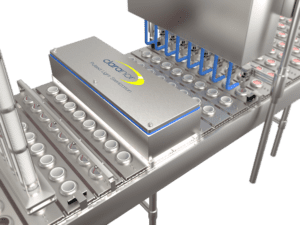

Our Cup and Lid Combi decontamination machine is a must-see solution for dairy and sauce filling lines. These industries are particularly sensitive to microbial contamination, especially molds, which can impact product quality and shelf life.

Thanks to Pulsed Light, our system delivers a high level of decontamination, instantly destroying microorganisms on cups without chemicals or water. With very low energy consumption, it combines strong microbiological protection with sustainability benefits.

UV MIDDLE-PRESSURE: A COMPLEMENTARY OPTION

In addition to Pulsed Light, Claranor also offers UV Middle Pressure (UV MP) modules for specific packaging applications, providing an additional option when obvious.

Range of cap, preform and bottle lid sterilizers

Discover Claranor’s Cap Decontamination Solutions, presented by our engineers

At Claranor, we offer three specialized cap decontamination solutions, all designed to meet the highest hygiene standards while ensuring easy integration, compact footprint, and adaptability to a wide range of bottling line speeds and product types.

FULLCAP – Enhanced Hygiene, Simplified Maintenance

Our FullCap solution sets a new benchmark for hygiene, decontaminating both the internal and external surfaces of sports and flat caps. Operating at speeds of up to 60,000 bottles per hour, it ensures an Extended Shelf Life (ESL) of over 60 days — all without chemicals and with minimal maintenance requirements.

INNCAP – High-Speed, Ultra-Clean Performance

Designed for high-speed bottling lines, the INNCAP solution delivers chemical-free decontamination at speeds up to 120,000 bottles per hour. Compatible with all cap types and sizes, it is the only solution on the market combining high efficiency and sustainability at such throughput.

ESSENTIAL – Smart, Cost-Effective Sterilization for Lower Speeds

For lines running at up to 16,000 bottles per hour, the ESSENTIAL solution offers an affordable entry into chemical-free cap decontamination. Leveraging the power of Claranor’s Pulsed Light technology, it outperforms traditional UV systems and reduces your Total Cost of Ownership (TCO).

PREFORM NECK

The new design of the Claranor preform machine reflects a major step forward in both performance and usability. With a modern, streamlined look, the equipment has been rethought to combine efficiency, reliability, and operator comfort. The redesigned structure offers a more compact footprint in two parts, allowing for easier integration into production lines while maintaining Claranor’s high standards of hygienic design. Clean lines, improved accessibility, and optimized ergonomics make maintenance and operation simpler and faster.

NEW: BOTTLE LID DECONTAMINATION

At PACK EXPO Las Vegas, we will also introduce our latest application: Pulsed Light decontamination of bottle lids. This innovative solution extends our portfolio to ensure safe and eco-friendly packaging hygiene for a wider range of formats.

Learn more about our cap decontamination solutions!

Primoreels – Claranor at Pack Expo 2025

Together, Primoreels and Claranor present a lidding solution that blends advanced decontamination with lightweight, sustainable packaging. The result is higher food safety, lower material usage, streamlined operations, and compatibility with existing production lines.

Primoreels and Claranor have joined forces to create a highly hygienic, low-impact lidding solution that integrates Pulsed Light decontamination for lids.

The combination yields:

- High microbial reduction: The pairing achieves reductions on the order of 4 log (i.e. 99.99 % reduction) in molds and bacteria.

- Respect for thin films: Because Pulsed Light is a non-thermal, dry method, it is well-suited to very thin lids that might be sensitive to heat or chemical processes.

- Line productivity: The integration reduces the need for frequent lid magazine refills and manual intervention, improving throughput.

- Packaging savings: The optimal layout and thin film compatibility help reduce material costs and over-packaging.

- Ease of adoption: This easy and clean lidding system is intended to simplify line upgrades and reduce complexity for producers.

A packaging sterilization project?

Meet our team

Dana Meyer, John Puthoff, Amaury Darmet, Benjamin Guerin, and Henrik Sahlberg will be present at Pack Expo Las Vegas to answer your questions and discuss how Claranor solutions and our partnership with Primoreels can help you achieve the highest packaging safety standards while minimizing environmental impact.

John PUTHOFF

CEO

Benjamin GUERIN

Area Sales Manager

Amaury DARMET

Business Developer