Equipment for production lines for sensitive products

Beverage, dairy product, sauce:

Bottled water, non-alcoholic beer, carbonated and non-carbonated drink, drinking yogurt, milk,

vegetable milk product, ketchup

Decontamination level:

3 à 5 log reduction on reference germs

Cap

Cap is a significant source of contamination on the line: it is not handled hygienically & is not heat treated like the preform.

The Claranor sterilization unit is integrated upstream of the capper

It incorporates the cap lock function. The cabinet is cleanable.

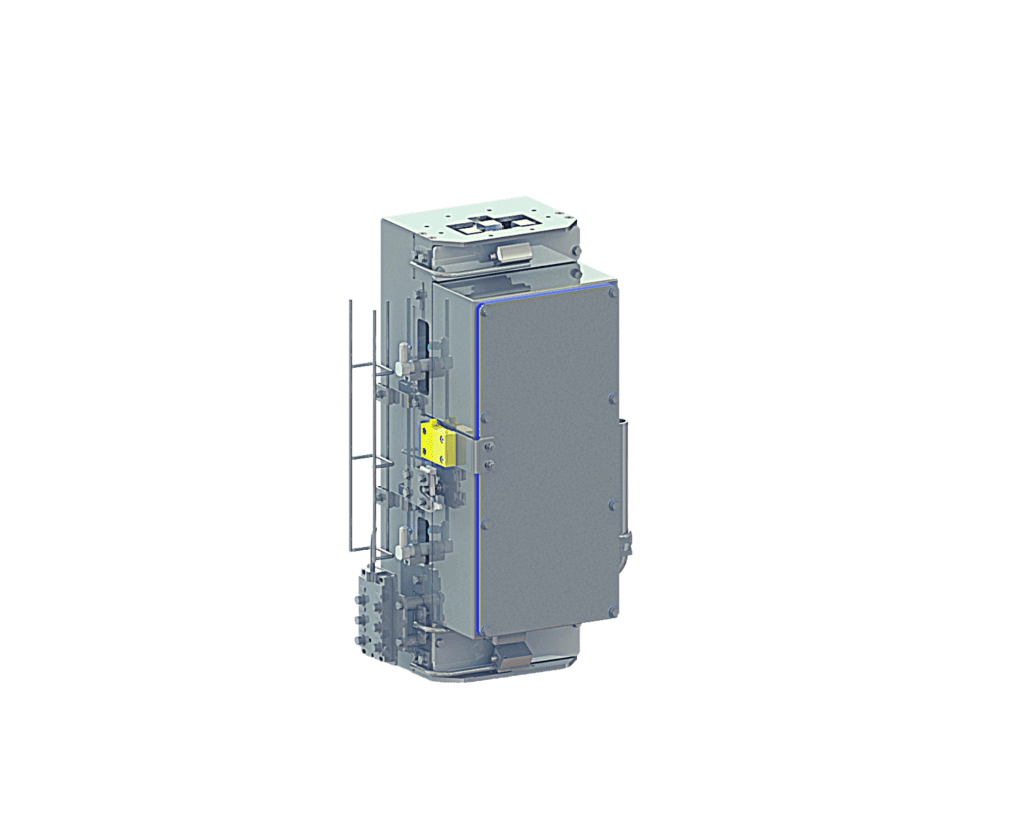

INNCAP

ESSENTIAL

up to 18.000 bph

Internal surface decontamination

Essential offers the efficiency of Claranor Pulsed Light with a low operating costs to producers of slower filling lines (<18,000 bph), bringing more efficiency than UV and a lower TCO.

Performances: Class IV VDMA, > 3 Log-Red on Aspergillus brasiliensis or Penicilium rubens.

Benefit from 2022 innovations: Hygienic design with a fully cleanable cap chute, COP-able and a IP 66 cabinet.

- Compact and easy to integrate on new or existing line

- Dry and non chemical

- Low energy consumption < 1 kw

- No heating time

Flat and sport caps (plastic, alu), Long neck, Crowns, T-cork, Twist-off

Standard cap size: 28-55 mm

Combination possible with preform or bottle neck sterilization.

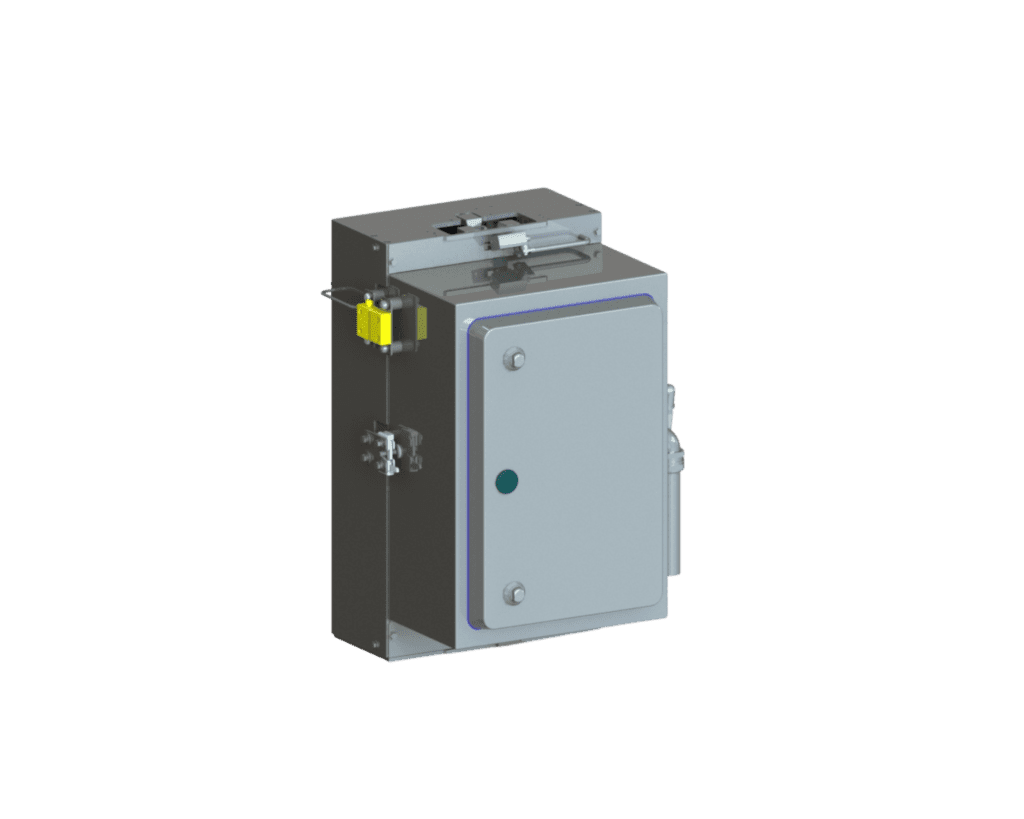

INNCAP

EVOLUTION & HISPEED

up to 100.000 BPH

Internal surface decontamination

The patented Claranor solution replaces chemical disinfection, UV being ineffective at these speeds. It is the only one on the market to offer such efficiency for high-speed lines. All types of caps.

Efficiency >>> UVC on molds

TCO <<< H2O2 for similar efficiency

Benefit from 2022 innovations: Hygienic design with a fully cleanable cap chute, COP-able, and an IP 66 cabinet.

- Inncap Evolution compact design

- Inncap Hispeed+75% lamp length for less frequent lamp change

- Multiple channel version for easy format changeover

- Combination possible with preform neck decontamination

- May be offered as an OEM kit

Flat and sport caps (plastic or alu)

long neck, crown, t-cork, twist-off

Standard cap size:

H: 8 to 38 mm

Ø: 20 to 68 mm

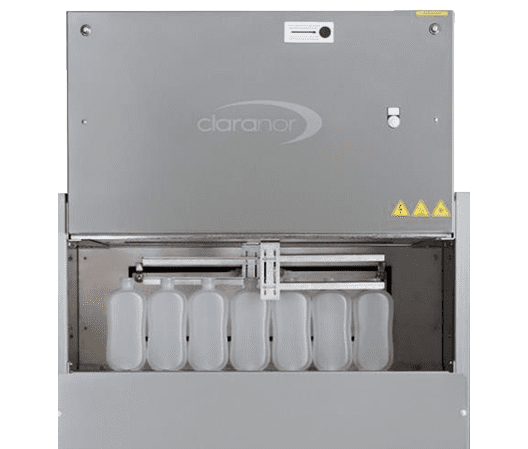

Fullcap

ESL > 60 days

up to 100.000 bph

Internal & external surface

Full Cap is a very compact and economical alternative to H202 tunnels: for the most sensitive water, even for the acid aseptic.

Performances: >4-5 Log-Red on molds

SENSITIVE WATER

3 Log-Red inside outside Aspergillus brasiliensis

on flat cap 30 mm

100.000 bph

ESL 60-120 AND HIGH ACID ASEPTIC

4-5 Log-Red inside molds and bacteria

3 Log-Red outside

50.000 bph

- Double side cap chute with 2 reflectors for internal / external decontamination

- Completely cleanable sterilizable cap chute

- No chemicals, low energy consumption

- No pre-heating time

- TCO <<< H2O2 for similar efficiency

- Patented design

Flat cap, Sport cap

PREFORM

Claranor sterilization unit is integrated on preform descent chute

upstream of the blowing step : preform neck,

on the conveyor upstream of the filler : bottle neck

Neck

up to 100.000 bph

Interior/exterior decontamination of the preform neck or the bottle

HPDE neck

The sterilization unit is integrated on the conveyor

upstream of the knives used to cut the “carrot / lost head” of the bottle

High speed line

up to 90.000 bph

Decontamination of the carrot/ lost head

The bottle is blown in a sterile manner and closed by a “carrot / lost head” which protects it from germs during storage. Sterilization of the lost head on the production line, before filling avoids any risk of contamination by the knives used to cut it.