INNCAN PULSED LIGHT DECONTAMINATION

Because of its sweetness and the growing demand for dairy products, sweetened condensed milk is increasingly used in many different cuisines around the world, and is also particularly popular for sweetening coffee.

Metal cans and can-ends now benefit from Claranor innovative solution. An efficient, economical, and energy-saving process. A cost-efficient alternative to flame for cans, to induction for can-ends.

Already 8 Sweetened Condensed Milk producers chose Claranor Pulsed Light equipment to reduce their energy consumption. What about you?

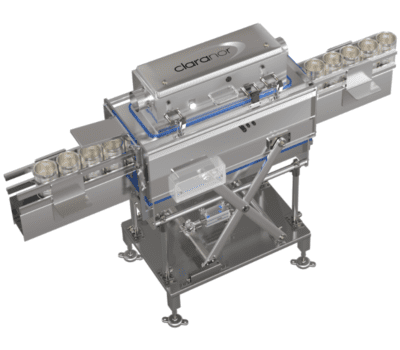

Our innovative cans decontamination machine with Pulsed Light

- Achieves up to 3 log reduction on Aspergillus brasiliensis. Moreover, our design department works closely with our microbiological laboratory to develop your solution that will ensure the requested microbiological reduction and will fit your retrofit or new filling line.

- Efficient, ecological, and economical solution, it allows the decontamination of your packaging at a low or high-speed rate, up to 1500 cans/ min.

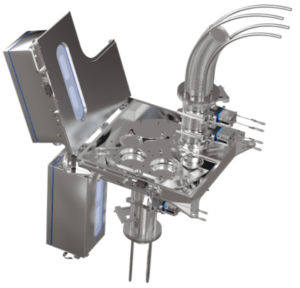

The equipment dedicated to the decontamination of can-ends

- Was developed in collaboration with Guylegall. It unstacks and conveys the can-ends. With 2 Pulsed Light sterilization cabinets which decontaminate 2 can-ends from above and below simultaneously.

- An athermal and instant treatment allowing 3 log reduction on Aspergillus brasiliensis

Advantages of the Claranor Pulsed Light Sterilization Equipment

- Very low energy consumption that offers a reduced TCO compared to flaming or induction and a carbon footprint reduction.

- Non-thermal, no heat generation in the working environment.

- Immediate availability, no preheating

- Instant treatment that allows the decontamination of your packaging,

- Allows the treatment of each pack and makes it easy for the production line stops and restarts.

- Suitable for new or existing filling lines.

- High decontamination level on Aspergillus brasiliensis.