EFFICIENCY, COMPACITY & SUSTAINABILITY

Pulsed light decontamination: an advanced technology adapted to producer challenges

Mother’s own milk is recognized as the best source of nutrition for infants. However, for convenience and economic reasons, powdered infant formula is widely worldwide used. With several crises (with various origins) in recent times, manufacturers challenge their practices to permanently improve the level of food- safety throughout the production line. And it appears that one of the main sources of contamination is the manufacturing environment (concentration and prevalence of E. sakazakii is high). Therefore, packaging sterilization is one of the critical points to be monitored.

Pulsed light packaging sterilization: a tried-and-tested technology

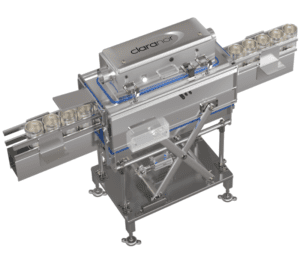

Claranor, the pioneer of Pulsed light in-line packaging decontamination for beverages and dairy products, brings to the infant powdered formula market, the advantages of the technology: A high level of efficiency, compacity, and sustainability. Moreover, suitable for high speed rates the standard cooling system is insured by a closed water system.

A technology adapted to infant formula production challenges

To achieve the dry sterilization needed for the infant powdered formula packaging a new cooling system by air has been designed. And it’s a whole range of decontamination equipment dedicated to the baby powder milk category that has been developed by our engineers: can, can end, cap with an integrated spoon of all shapes, sizes, or material can be instantaneously treated in line by pulsed light.

UPGRADE DECONTAMINATION ACCURACY AND PRODUCTION UPTIME

Instant treatment, the pulsed light technology offers optimal accuracy, reproducibility of the decontamination, and a high availability (100% uptime). Plus, it allows the treatment of each pack and makes it easy for the management of production line stops and restarts.

Proven efficiency, it ensures similar or higher packaging decontamination than conventional methods. Moreover, the microbiological decontamination is measurable and validated by an independent laboratory the Fraunhofer Institute IVV.

Can sterilization

Our Pulsed Light solution remains with a strong advantage: the heat is not released in the environment around the conveyor but eliminated outside the production room.

PULSED LIGHT ADVANTAGES AT A GLANCE:

• High level of efficiency

• No heating around the treatment zone

• Compact, easy to integrate on new or existing line (<1,5m)

• Instant treatment (no pre-heating time)

• Lower running costs

• Sustainability (low energy consumption, no hazardous waste management)

We now also offer UV packaging decontamination solutions. For inner decontamination of the milk powder can-end & lid scoop cap, the INNCAN unit exists in a multi-format UV tunnel.

UV ADVANTAGES AT A GLANCE:

• Dry and chemical-free solution

• UV dose monitoring

• On-site qualification possible

• Decontamination by continuous exposure to LP UV-C lamps

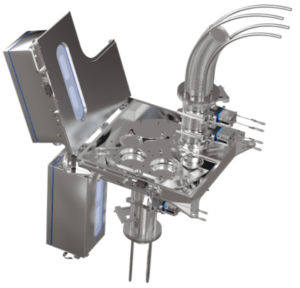

Can-end sterilization

On top of the powder milk can sterilizer, Claranor develops a Can End sterilizer.

Integrated around the can end conveyor, the sterilizer decontaminates instantaneously the both sides of the can end to avoid any contamination during the restacking.

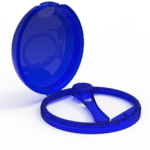

Closure with integrated spoon sterilization

To offer a complete solution of the whole packaging, Claranor designs a new optical cabinet adapted to the Closure with integrated spoon.

For a full decontamination of the closure, a collaborative approach of innovation with Aptar, leader in dispensing system, has been adopted to provide manufacturer an innovative version of the Neo by Aptar closure.

Designed with a transparent spoon, it allows the decontamination of all the surface in contact with the product including the surface under the spoon.