Tethered caps, alu caps or crowns, alu cans, and lids decontamination:

What’s new?

Brau Beviale 2023 was the perfect exhibition to display our Pulsed light sterilization solutions

for water, beer, and other sensitive beverages.

Anna Moutier, Annegret Nied, and Christophe Riedel appreciated your visit during the Brau Beviale 2023 exhibition that took place in Nuremberg, Germany.

You were numerous looking after chemical-free decontamination solutions for beverage containers. Indeed, we had lots of requests around the circular economy: retrofit with tethered caps due to the new EU regulation; the tethered caps becoming mandatory in the area in July 2024. But also aluminum caps or crowns with liners where chemicals oxidize the cap and could be stuck under the liner.

Plus we had lots of decontamination inquiries on aluminum cans and lids decontamination, due to the rising demand for metal cans in the beverage industry.

Annegret Nied, our Customer Service Manager was happy to present our new Client support organization and services.

If you missed the show, discover hereafter our efficient and sustainable decontamination solutions.

Find out more information on our fully redesigned range of cap machines, our equipment dedicated to preform and bottleneck sterilization, and our innovative machine for can and lid decontamination, JUST ONE CLICK AWAY!

New range of cap sterilizers at Brau Beviale 2023

The trend toward natural products, cold filling, and preservative-free drinks made the beverages and dairy even more sensitive to microbiological contamination.

To support producers in the hygienic upgrades, while improving their sustainable practices, Claranor designed a range of 3 compact and highly efficient cap decontamination machines to be integrated into bottling lines:

- INNCAP :

The Claranor Ultra-clean cap decontamination equipment is dedicated to high-speed lines reaching a speed up to 120 000 bph. Working on all types and sizes of caps, it is the only one on the market to offer such efficiency with that speed. - ESSENTIAL:

A cost-attractive solution, suitable on low or medium speed lines with a speed up to 16 000 bph. It offers the efficiency and low operating costs of Claranor Pulsed Light to producers of slower filling lines, with higher efficiency than UV and lowers TCO. - FULLCAP:

Perfect for sports caps as well as flat caps, it decontaminates the internal and external surface of the cap with a high speed of up to 60 000 bph, it ensures an ESL > 60 days. Compact, and economical, it’s an excellent alternative to H2O2 tunnels: for the most sensitive refrigerated products, and even for the acid aseptic.

Learn more about our cap decontamination solutions at Brau Beviale 2023!

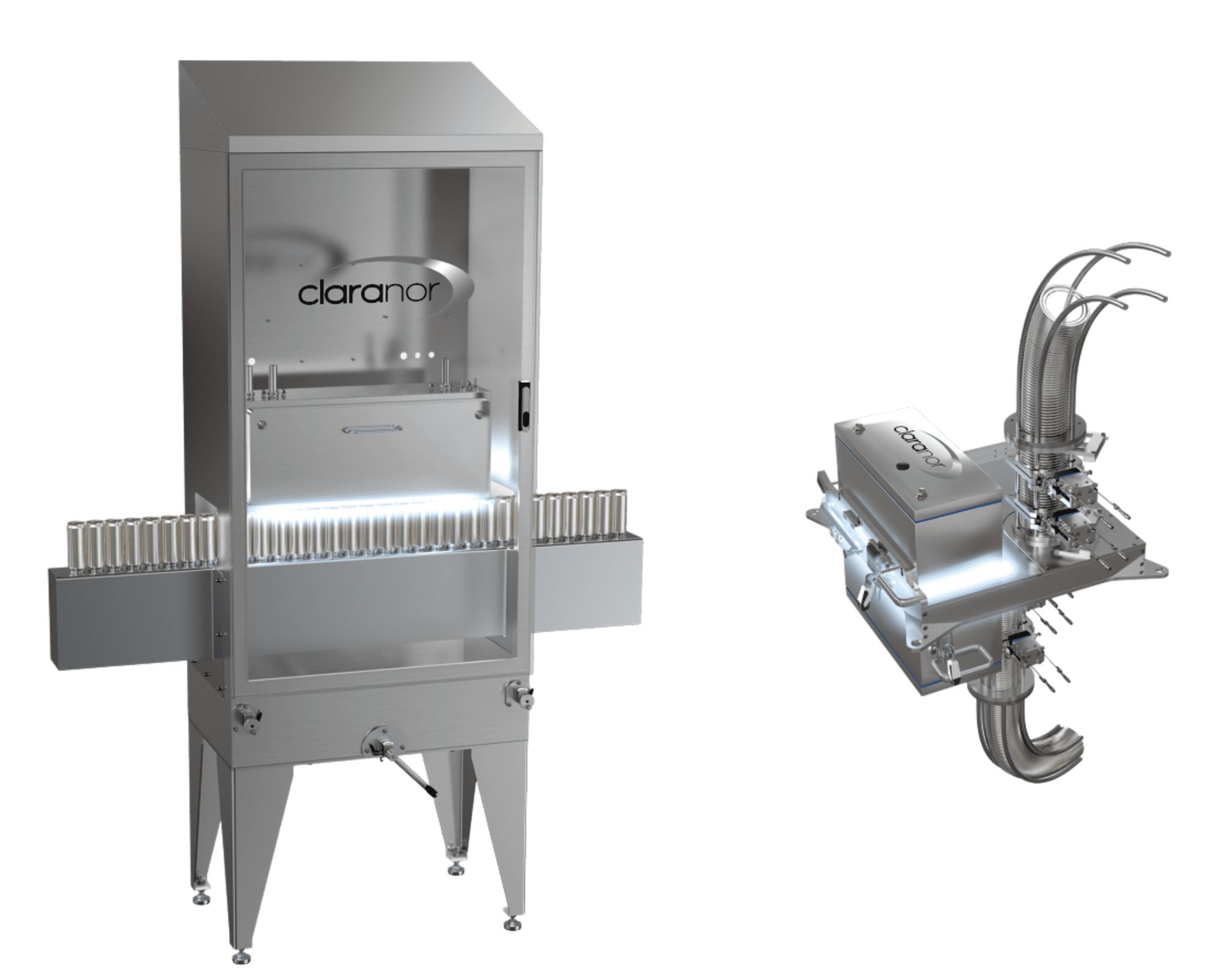

Aluminum can & lid decontamination equipment

Claranor offers a global solution to decontaminate your beverage packaging: aluminum cans and lids benefit from Claranor decontamination solutions.

Suitable for new and retrofit filling lines, our efficient and tailor-made equipment enables an instant and chemical-free decontamination of cans. Also, both sides of the can-end and the lid of the can are decontaminated at the same time to avoid recontamination during restacking.

Its compactness and hygienic design, make the cleanability and the mechanical integration on the filling line easier.