Claranor and the cap market

In 2021, 247 Claranor cap machines were sold worldwide, 110 of which were for the water market, 120 for the dairy market, and 40 for other products such as juices and sauces.

The adaptability of Claranor pulsed light decontamination solutions

As far as the beverage market is concerned, the use of pulsed light to sterilize caps is a relevant and economical solution, already used by a number of beverage giants.

There are many benefits of packaging decontamination using pulsed light in the beverage sector: sterilisation without chemicals and risks of chemical residues, reduction or elimination of ozone in water. The possibility to reduce or eliminate the use of preservatives for example.

Essential

Ultra-clean

Full cap

Claranor pulsed light decontamination on the water market

110 Claranor machines on the water market

For the last 15 years the market for bottled water has been exploding. The consumption of still bottled water has increased by 200% since 1999 (Canadean study). If water consumption in France is starting to stagnate, it is experiencing an explosive evolution worldwide. Spring water and natural mineral water are rare and in great demand.

The evolution of the water market in a few figures:

- 10% increase each year in Mexico

- 230% increase between 2008 and 2012 in China

- The United States is the world’s largest consumer

Recently arrived on the market over the last ten years, flavoured waters have also been a great success. It is currently the most dynamic segment of bottled waters. Numerous brands are developing ranges of flavoured waters as a result of the enthusiasm of consumers around the world.

However, consumers are placing increasing importance on the ecological side of bottled waters. As a result, the major players in the market must take into account the considerable impact they have with their packaging.

- Some waters or flavored waters are more sensitive and require the sterilization of the packaging to ensure their conservation

- The decontamination of packaging with Claranor Pulsed Light is chemical-free and protects the organoleptic qualities of the water and its source

On this market 2 types of machines used:

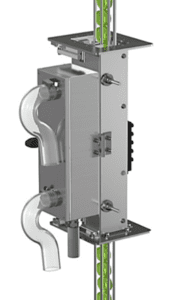

- Essential: for large containers up to 5 gallons, flat caps and a low or medium output: up to 16 000 bph

- High speed: flat or sport caps, ultra-clean line, high-speed line up to 100 000 bph

Decontamination by Claranor pulsed light and dairy products or liquid vegetable alternative

120 equipments for dairy products

Drinkable dairy products have always been popular with consumers from all over the world. But if we look at the current trend at that level, more and more people are turning to alternatives to conventional dairy products with vegetable components.

Indeed, from a health and digestive point of view, but also in terms of taste or in an ethical sense, consumers are increasingly fond of this kind of alternative. To meet this demand, manufacturers innovate and many new products in this trend are emerging.

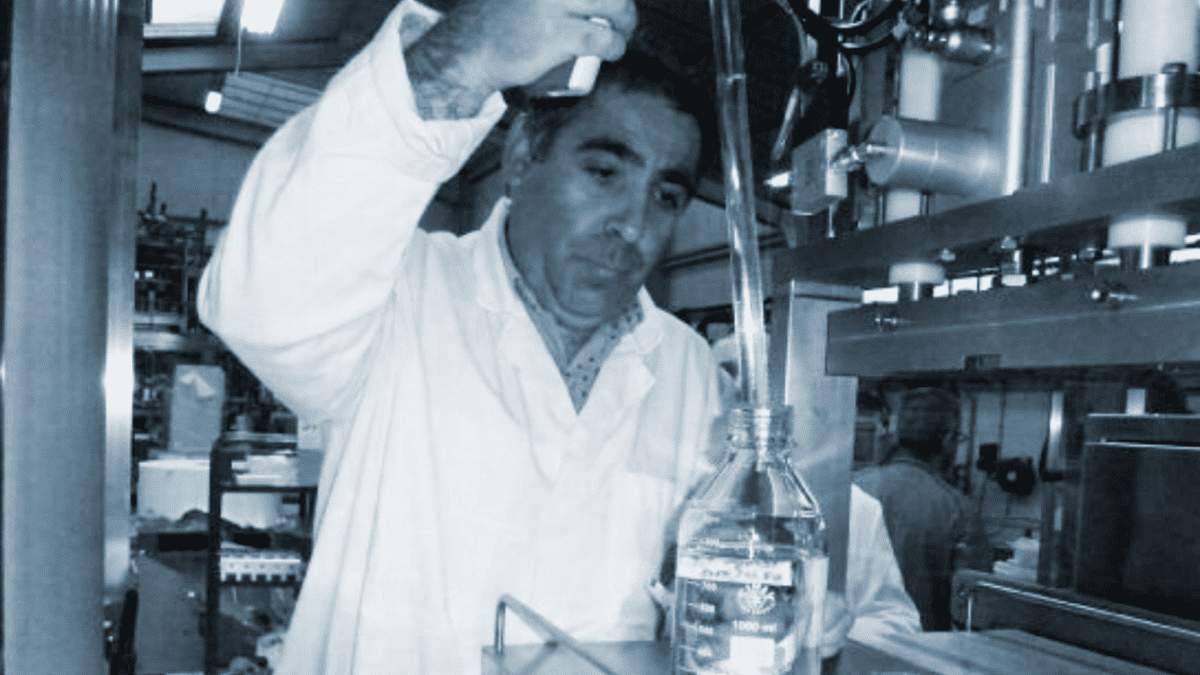

The pulsed light decontamination technology is also applicable for dairy or vegetable alternative packaging. Dairy products and vegetable alternatives are naturally more sensitive to and it is moulds therefore necessary to ensure that the packaging is sterile and clean before filling these products.

Claranor’s pulsed light technology excludes any risk of chemical residue in the packaging and protects your product throughout its shelf life.

It is important to note that these products, given their composition and manufacturing process, are much more sensitive than conventional dairy products. It is therefore necessary to take precautions in terms of packaging decontamination.

Depending on the line speed or the decontamination required, 3 types of Claranor machines are available:

- Essential: for large containers up to 5 gallons, flat caps and low speed: 16 000 bph

- High speed: from small to large containers, for all types of caps and at a very high rate: 100 000 bph

- Full cap: sterilises the inside and outside of the cap for extended shelf life, flat and sport cap, medium speed: 60 000 bph

The other markets of Claranor

About forty machines on other markets such as juices and sauces like ketchup.

The juices

After a strong increase in consumption, fruit juices have been stabilising for about ten years. However, many innovations are making their appearance, for fruit juices that are better for health and the environment, with packaging designed for recycling and circular economy. As a result, consumption has been increasing for some time and it is thanks to these “healthy” innovations that the products have been so successful. The current trend in the world is to turn towards products that are healthier for the body and it is in this sense that preservative-free, freshly pressed or organic products are becoming a real success.

Ketchup

Due to the increasing demand for higher quality products, cold filling is often chosen by the industrialist. It preserves the organoleptic qualities of the product. The Claranor decontamination by Pulsed Light offers a process that allows a sterilisation of the packaging and the preservation of the product.

The packaging

Claranor pulsed light is a non-chemical and athermal surface process. It respects the quality of all types of material: PS, PP, PE, metal caps, with or without aluminium seal. On caps with a lid, it avoids the risk of chemical product residues under the lid.

Standards and materials

The standards for packaging, in this case, caps, aim to reduce plastic pollution. By 2024, all plastic bottle caps will have to be attached to their bottle (up to 3L). In other words, all the caps must remain on the bottle, the consumer must be able to open and use his product without having a loose cap, that he can lose, or that can be found more easily in nature.

This concept will become compulsory for all plastic bottles, including sparkling water bottles, which cannot benefit from this innovation at present because of the need for the necessary progressive degassing.

With regard to the materials used, here too many current and future standards encourage manufacturers and therefore consumers to favour eco-responsible and/or sustainable packaging.

The EU is launching the race for “eco-design” and is therefore insisting that manufacturers make it compulsory to include recycled PET in bottles up to 25% by 2025 and 30% by 2030.

In a movement of circular economy, budgets are even allocated to enable manufacturers to promote this ecodesign and encourage innovation in this direction.

The results of microbiological tests on all types of caps treated with Claranor Pulsed Light are available on request.

You innovate with new recyclable materials or with new types of caps. You wish to use our sterilisation solutions, send us samples or photos of your packaging so that we can confirm feasibility.

If you have a cap sterilization project

Our team of experts will be happy to discuss this with you.