Sustainability and energy savings for the benefit of beverage manufacturers!

Claranor Pulsed Light will be at Drinktec 2022 , the meeting place for the beverage and liquid industry, in Munich, Germany from September 12 – 16, 2022.

On this occasion, we will have the opportunity to present our 6 innovative pieces of equipment that offer the efficiency of Claranor Pulsed Light for the dairy, plant-based drink, and beverage industries.

Take this opportunity to discover our equipment, our technology and discuss with our team! Christophe, Anthony, and Benjamin will be pleased to welcome you.

Booth C4-225

Metal Can, can-end, and lid decontamination

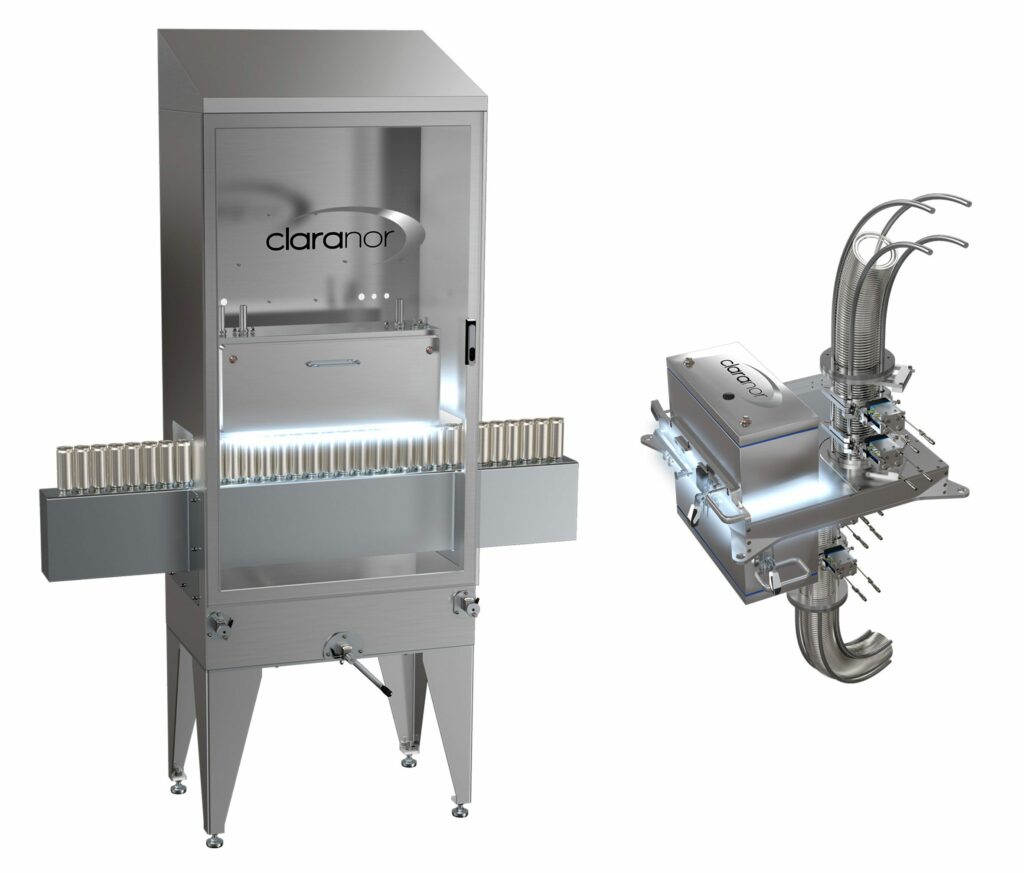

Claranor has designed a Combi that uses pulsed light to decontaminate the inside of cans and their lids. This solution is the perfect hygienic decontamination solution for ultra-clean can packaging lines.

Indeed, to avoid over-pasteurization, which alters beverages and consumes a lot’s water and energy, Claranor has designed a solution for decontaminating the inside of cans & their lids with pulsed light: the Claranor Combi Cans & lids.

In fact, the advantages are the significant energy savings and the cleantech, without water or chemicals. It offers efficient and instant decontamination, which will eventually be integrated into high-speed filling lines. It ensures that all cans and lids receive the same treatment.

Moreover, the compactness eases the integration into new or existing lines. Its modularity allows adapting to different can formats. Plus, this solution offers the advantage of being able to reduce the thickness of the metal.

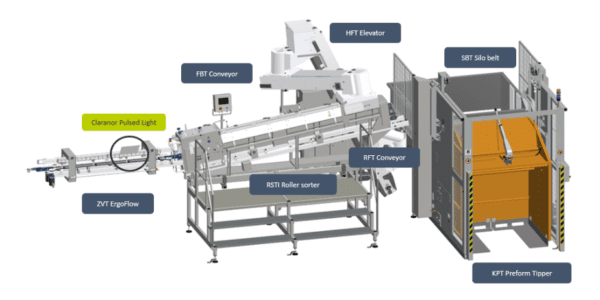

Tanner Ergoflow with Pulsed Light

Preforms ergonomic flow and decontamination

Claranor, in collaboration with Tanner, presents Ergoflow with Pulsed Light. The integration in native on the Tanner Ergoflow of a Claranor Preform decontamination module allows beverage producers to achieve a hygienic filling of their sensitive products such as fruit juices, liquid dairy or nondairy products, energy drinks…

Thus, they benefit from a turnkey solution with a reduced Pulsed Light Capex and Opex, and a higher efficiency due to an active regulation of the preform flow and the instant Pulsed Light decontamination

New hygienic range of cap sterilizers!

Claranor brings a fully redesigned range of cap sterilizers to beverage producers, that allows the filling of products, from the least to the most sensitive.

With more than 400 Claranor’s Cap decontamination units installed and several international patents in this field, our team has a valuable design expertise. The new range addresses each critical point: hygienic design, the possibility of integrating cleaning in place and mechanical interfaces that prevent any blockage, first and last cap management…

Depending on the client request, Claranor offers inner decontamination or inner & outer decontamination of the cap.

INNCAP Essential

INNCAP Highspeed

FULLCAP

- INNCAP Essential, up to 16,000 bph, 3 log reduction. All the advantages of Claranor Pulsed Light at an attractive price.

- INNCAP Original, 50000 bph, >3-4 log

- INNCAP Highspeed up to 120,000 bph, >3log

- FULLCAP, for ESL>60 days and High acid aseptic, > 5 log

To find out more, make an appointment with our team !