Claranor and Kombucha

Kombucha, an ancient fermented tea-based drink, has captivated the health and wellness world thanks to its probiotic benefits. However, like any fermented beverage, food safety is a top priority.

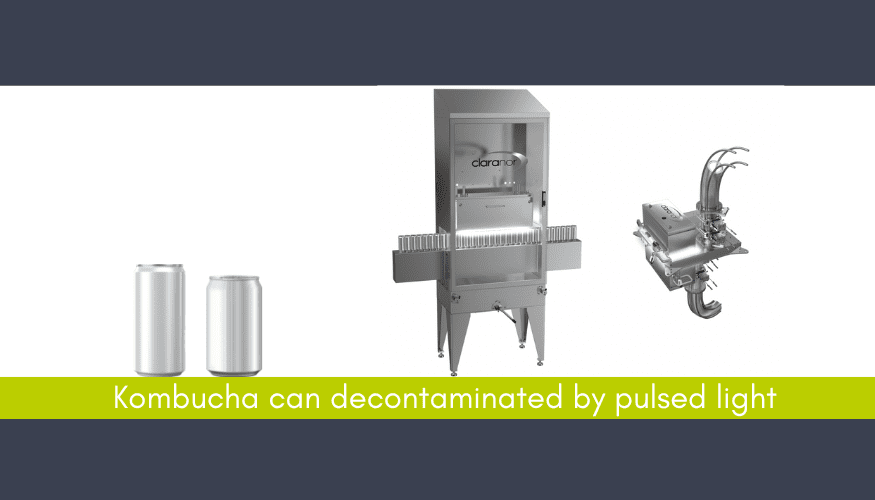

Pulsed light sterilization offers an effective solution for decontaminating kombucha packaging while preserving its qualities.

Kombucha: a fermented beverage with benefits

Originating from Chine, kombucha is made by fermenting sweetened tea using a symbiotic culture of bacteria and yeast (SCOBY). This process produces organic acids, enzymes and probiotics that benefit digestive and immune health. The drink is aslo prized for its antioxidant propertires, vitamins, and low sugar content after fermentation.

The growing popularity of kombucha has led to increased industrial production, requiring rigorous measures to ensure product safety and quality

The challenges of Kombucha packaging decontamination

One of the critical aspects of kombucha production is the decontamination of packaging. Bottles and containers must be free of pathogenic microorganisms that could compromise the safety of the final product. Traditional sterilization methodes, such as thermal pasteurization, can affect the probiotics and flavor of kombucha.Therefore, the industriy seeks alternative methodes to maintain quality while ensuring safety.

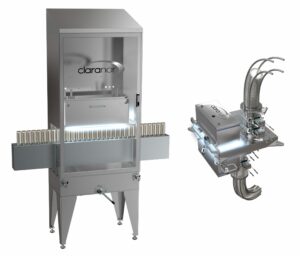

Pulsed Light sterilization technology

Pulsed light decontamination is a technique that uses intense flashes of light to destroy microorganisms on packaging surfaces. This process relies on burts of broad-spectrum white light, visible and infrared light emitted over very short durations (in the range of microseconds).

Claranor Pulsed Light decontamination benefits:

- efficiency: capable of significantly reducing microbial load in a very short time

- Preseervation of product properties: Unlike thermal methods, it does not affect the organoleptic quality and beneficial properties of Kobucha

- Environmental friendly: no chemical reisdues or excessive water use.

How does pulsed light work on a Kombucha production line?

In the context of kombucha production, pulsed light is primarily applied for decontaminating the surfaces of can and can end before filling. Here’s how the process generally unfolds:

- Preparation of packaging: cans are cleaned to remove physical debres

- Pulsed light Sterilization: cans are exposed to pulses of light. The duration and intensity of the pulses are adjusted based on the type of material and the required level of decontamination

- Filling and sealing: Sterlized bottles are immediatly filled with the kombucha and sealed to prevent recontamination

This methodes ensures that kombucha remains as pure and flavorful as possible while meeting the highest food safety standards.

Adopting pulsed light sterilization in kombucha production represents a significant advancement for the industriy. It not only ensures consumer safety but also preserves the precious probiotic qualityes of the beverage. By integrating this technology, kombucha producers can meet the growing demande for healhy and natural products while minimizing their environnemental impact.

Pulsed light offers a solution for effective decontamination that respects the organoleptic properties and nutritional qualities of kombucha, paving the way for a new era of safe and sustainable food production