Claranor in the UK since 2012!

In 2016 the UK government implemented a sugar-tax policy aimed at reducing diet-related diseases. The UK soft drinks industry levy was at the forefront of progressive policy design when announced in 2016. Targeted at manufacturers, its tiered structure imposes higher taxation on products with higher sugar content, providing motivation to reformulate to reduce sugar levels. The levy applies to yogurts and dairy products as well as soft drinks.

Three years later, in 2019, the total sugar content in yogurts has been reduced by 13% and that in drinks, particularly soft drinks, by 30%.

This reduction in sugar makes the products susceptible to bacterial and mould growth and it is, therefore, necessary to use sterilized packaging.

Claranor’s Pulsed Light decontaminates packaging and prevents the growth of bacteria and mould. Dry sterilisation is chemical-free and avoids any risk of chemical residues.

Since 2012, Claranor has been operating in the UK to offer its Pulsed Light sterilisation solutions. Double-digit numbers of machine are already in operation.

Claranor has innovated to offer solutions to meet the needs of its customers: high or low speed, caps, and preforms, or cups and lids. More recently Claranor technology is used in the decontamination of films and metal cans, lids for milk powder and sweetened condensed milk containers.

Keith, your contact for the UK and Ireland markets

Any questions about packaging sterilization or Pulsed Light, please contact him!

Claranor Pulsed Light decontamination on dairy products

The UK is the eleventh largest milk producer in the world with 15 billion litres of milk in 2020.

(source Statista 2021)

Ireland produced 8 billion litres of milk in 2020, with annual volume growth at around 15%.

The sensitivity of dairy products and their short shelf life means that manufacturers need to take precautions in terms of packaging sterilisation.

Claranor’s Pulsed Light technology offers a decontamination solution that eliminates bacteria and moulds without chemicals and therefore without disinfectant residuals in the packaging. This innovative solution allows compact sterilisation, which can be integrated into new lines or retrofitted to existing lines.

Examples of hight throughput rates are:

- 2014: plastic cap for milk on a new line at a rate of 16,500bph

- 2017: 2 machines on new lines to sterilise plastic caps at a rate of 10,000bph

Claranor Pulsed Light decontamination and plant-based alternatives

Since 2018, there has been an increase in the consumption of plant-based milk in the UK. Indeed, sales of plant-based milk products, such as oats, hazelnuts, almonds, and coconuts, have increased by 20% due to a change in consumer preferences. Vegetarian and vegan diets are increasingly prominent in the UK. Consumption of alternative products has therefore been boosted by the increasing ease of finding these products in supermarkets. Health, environmental and ethical concerns are driving this movement.

Dairy alternatives are naturally more susceptible to bacteria and mould and therefore it is important to decontaminate the packaging.

Claranor’s Pulsed Light Sterilisation is a good alternative to conventional wet sterilisation systems, offering an economical and environmentally-friendly solution.

Since 2015, a market-leading food producer has used Claranor for 3 projects:

- 2015: cup and lid on a retrofit line a requirement of 3-log decontamination

- 2019: plastic cup and lid on a new line at 25 strokes per minute with a requirement for 3-log decontamination on A. brasiliensis

- 2021: plastic cup and lid on a new line at 30 strokes per minute with a requirement for 3-log decontamination on A. brasiliensis

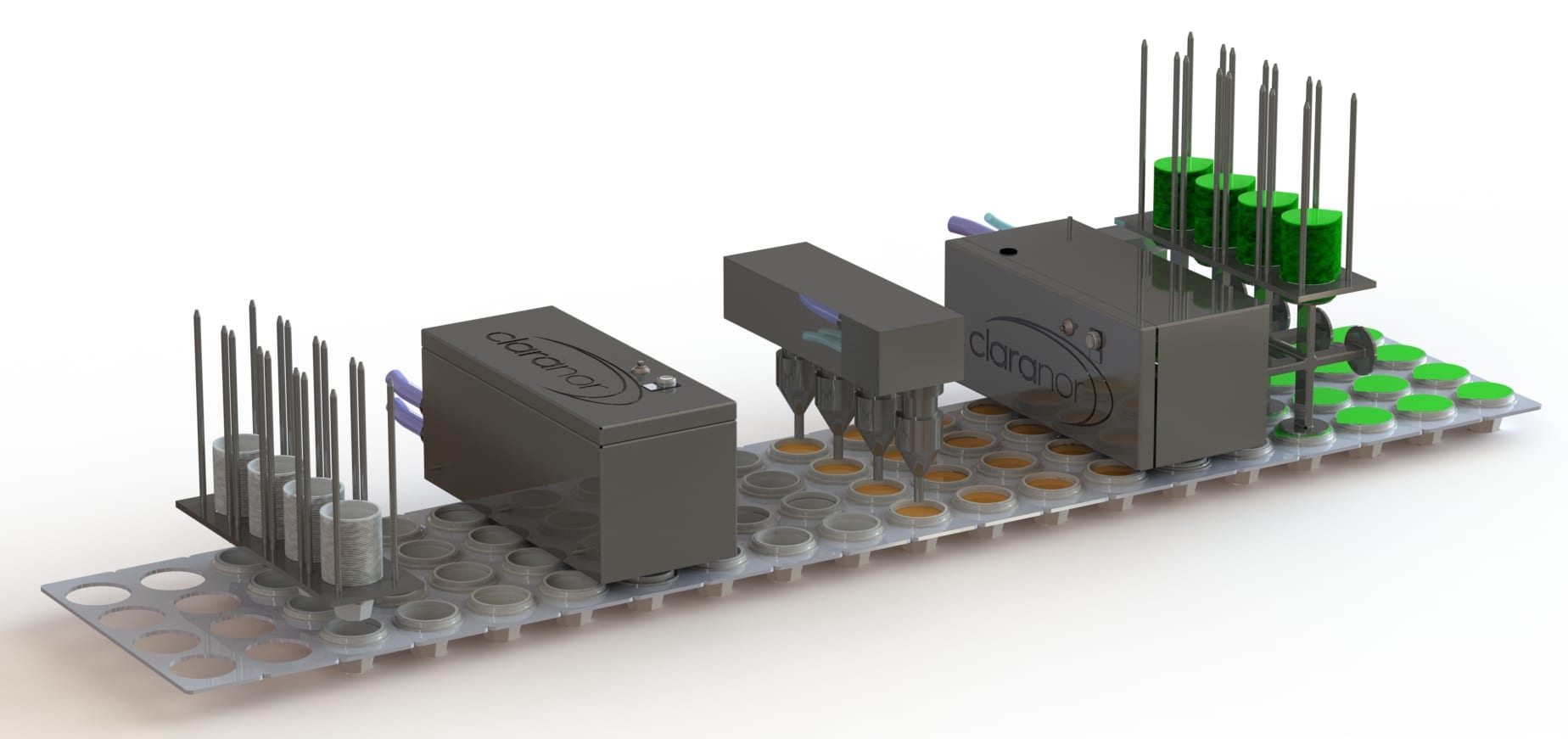

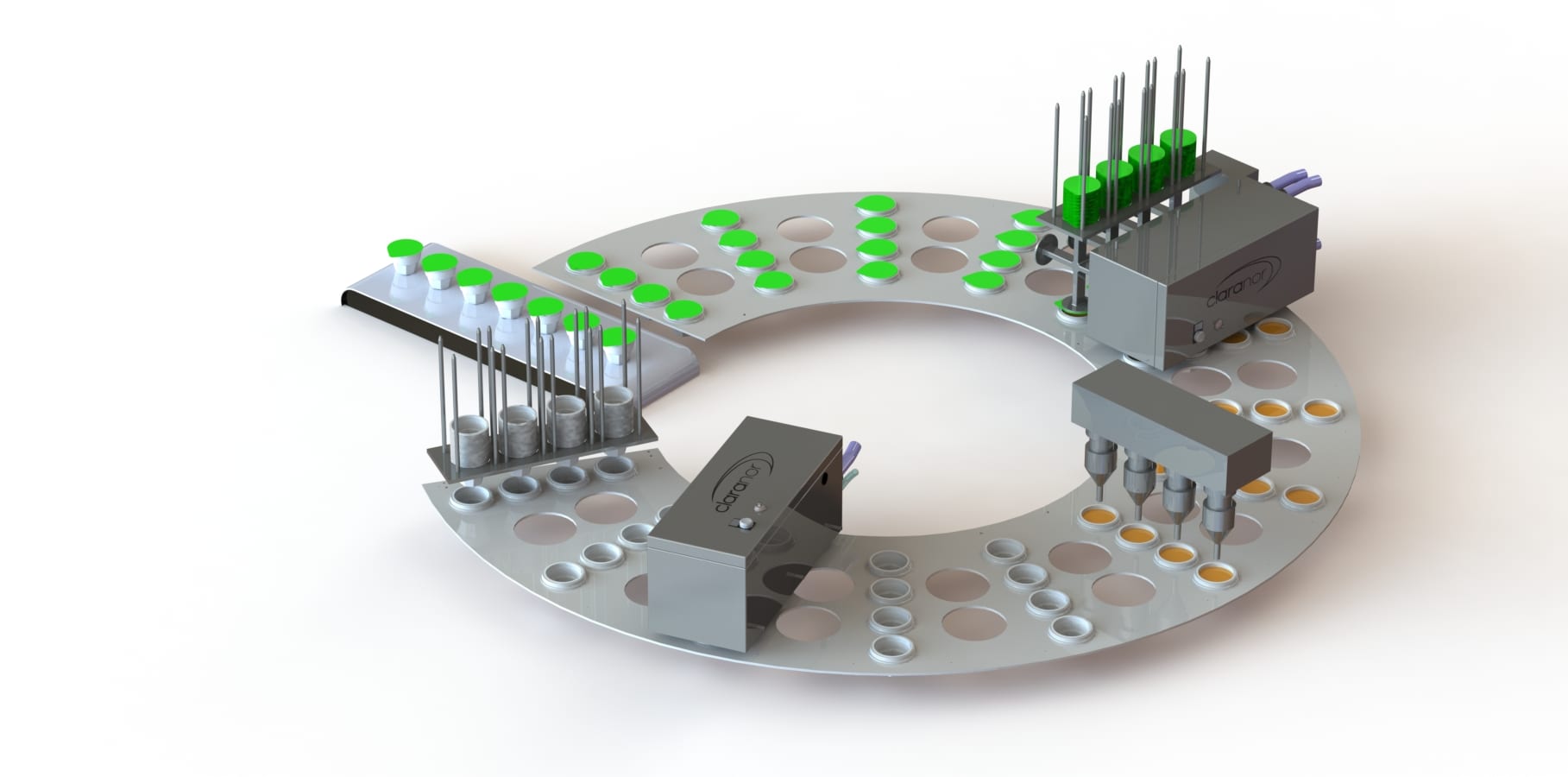

Compact, Claranor sterilisation units can be integrated on linear or rotary filling line

Claranor in th UK drinks market

Waters and flavoured waters:

Like yogurts, since 2016 beverage producers have been encouraged to reduce sugar levels in the drive to improve consumer health.

Bottled waters (reconstituted purified waters) and flavored waters are sensitive products because they are modified. The reduction of sugar increases the sensitivity of flavored waters. It is therefore very important to protect these products by decontaminating the corks and bottlenecks.

Claranor Pulsed Light sterilisation has several advantages:

- No risk of disinfectant residual in the packaging, nor of neoformed contaminants

- The organoleptic qualities and properties of the water are preserved

- The process is suitable for both small and large containers: up to 25 litres ; and for low, medium, or high speeds: up to 100,000bph

Since 2013, a leading beverage producer has chosen Claranor as their partner in packaging sterilisation. Multiple lines are equipped with the Claranor Pulsed Light sterilisation system including:

- Decontamination of caps for medium-sized containers -> 2L for water;

- Decontamination of 28 mm flat plastic caps on a retrofitted line at a speed of 19 200 bph for flavoured water;

- Decontamination of a 24 x 15mm flat plastic cap on a new line at a rate of 54,000 bph for a 3 log decontamination for water;

- Decontamination of 33 x 28mm sport plastic cap on new line at a rate of 54,000 bph for 3 log decontamination of water

Juices

Claranor’s Pulsed Light decontamination solutions simplify the process and avoid the need to turn the product upside down to decontaminate the cap, as well as reducing or eliminating preservatives in the products.

Fruit juices are also sensitive products.

In 2014, a UK bottler asked Claranor to find a Pulsed Light sterilisation solution to suit their requirements for an existing line: a plastic preform for juice on a line retrofitted at a speed rate of 21,600bph

If you have a sterilisation project in the UK or Ireland,

our partner will be happy to discuss it with you

MC ELWAINE TECHNICAL SERVICE: your partner in the UK or Ireland

MC ELWAINE is our exclusive contact in the UK. Keith Mc Cracken and his team are ready and available to support your project.

Please do not hesitate to contact Keith Mc Cracken who will be happy to provide you with information on Claranor's Pulsed Light and our packaging decontamination solutions.

The MC ELWAINE TECHNICAL SERVICE team will commission and maintain your equipment on site for Claranor, as well as providing technical support.