Equipment for production lines for sensitive products

Large containers give products higher sensitivity and decontamination of the packaging is needed.

Sensitive drink, refrigerated dairy dessert,

Shelf life from 50 days (neutral products) to 60 days (acid products),

Water, low alcohol beer and wine, yogurt, cream, cottage cheese, sauce

Decontamination levels:

3 to 5 log reduction on microorganism of reference

5 Gallons Cap

The cap is a significant source of contamination on the line: it is not handled hygienically, and is not heat treated like the preform.

The Claranor sterilization unit is integrated upstream of the capper.

It incorporates the indexing system. The optical cabinet is cleanable.

Essential

Up to 16.000 bph

- Decontamination of the internal surface of the cap, surface in contact with the product.

- Essential offers the efficiency of Claranor pulsed light and its low TCO to producers of low and medium speed lines (<16,000 bph), providing more efficiency than UV and lower TCO.

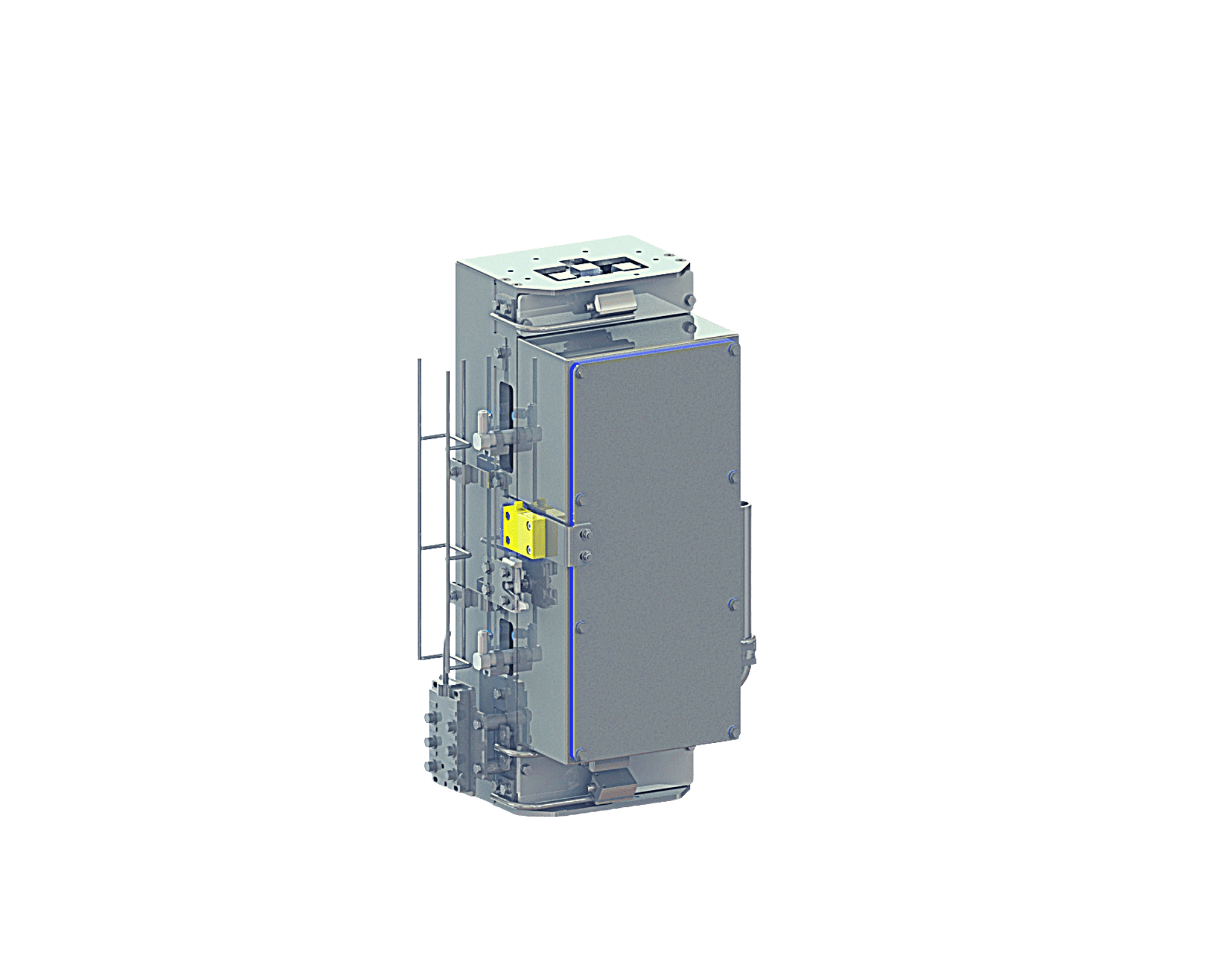

Lid and bucket

The Claranor online sterilization unit

is integrated upstream of filling

Linear filling

up to 1000 buckets / hour

Decontamination of the internal surface.

Bucket and tray up to a capacity of 10 L.

- Synchronization with the production line

- Instant processing

- Non thermal it respects the packaging

- No chemical residue

- Economical and sustainable thanks to its very low energy consumption

The integration of the equipment and the optical shielding of the line (optical protection) can be carried out by Claranor on a new or existing line.

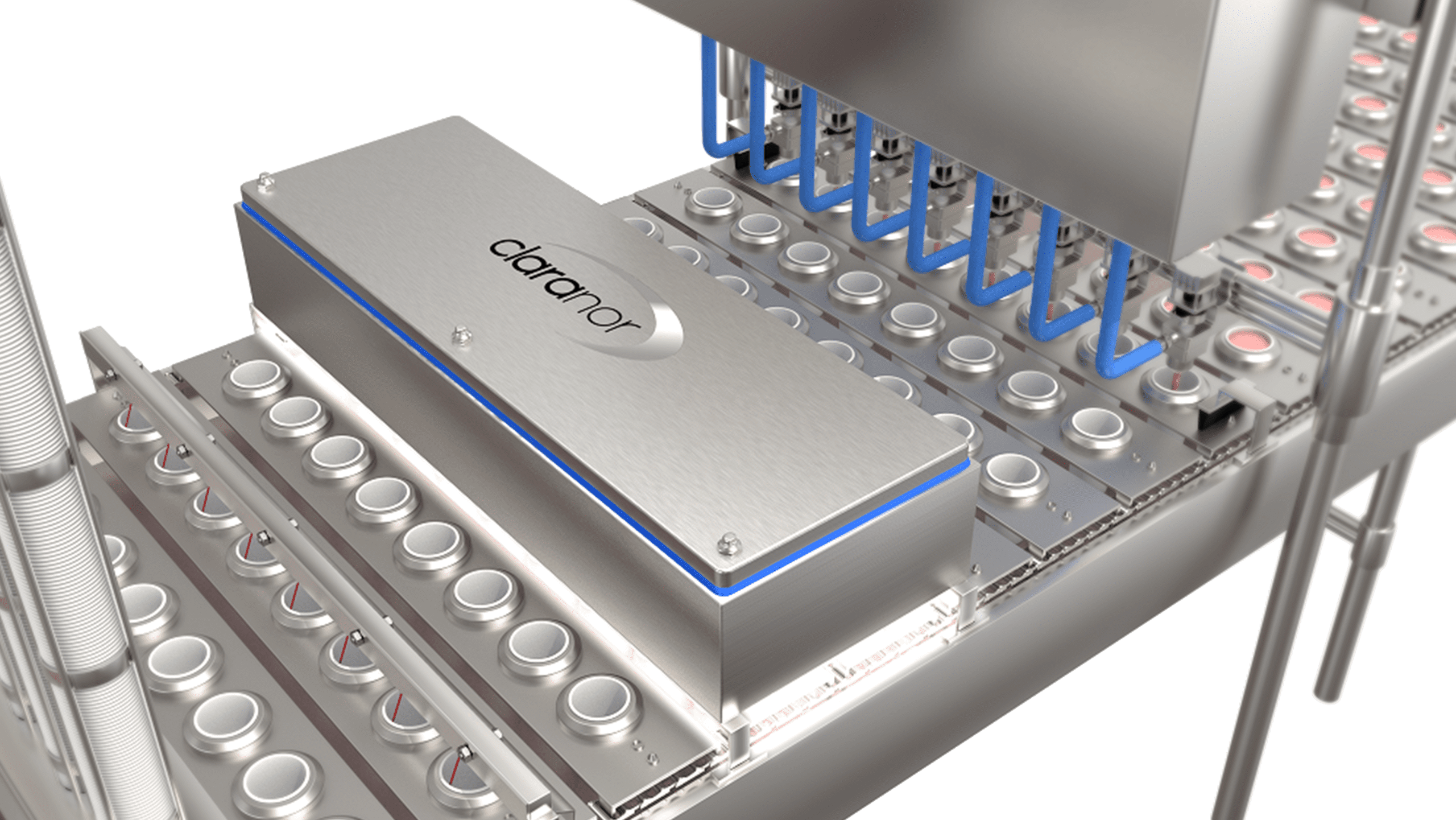

FILM for BAG-in-BOX

Claranor’s online sterilization unit is integrated

upstream of the forming step

Up to 20 m / minute

Decontamination of one or both sides

All types of materials (PE, PP, LDPE, Pla, composite…)

Max format:

Configuration adaptable to the bagger, vertical or horizontal

Claranor can integrate equipment on existing line

- Synchronization with the production line.

- Instant processing.

- Non-thermal, it respects the packaging.

- Without chemical risks.

- Economic and sustainable thanks to its very low energy consumption.