Just click on the pictures of the machine to download the data sheet

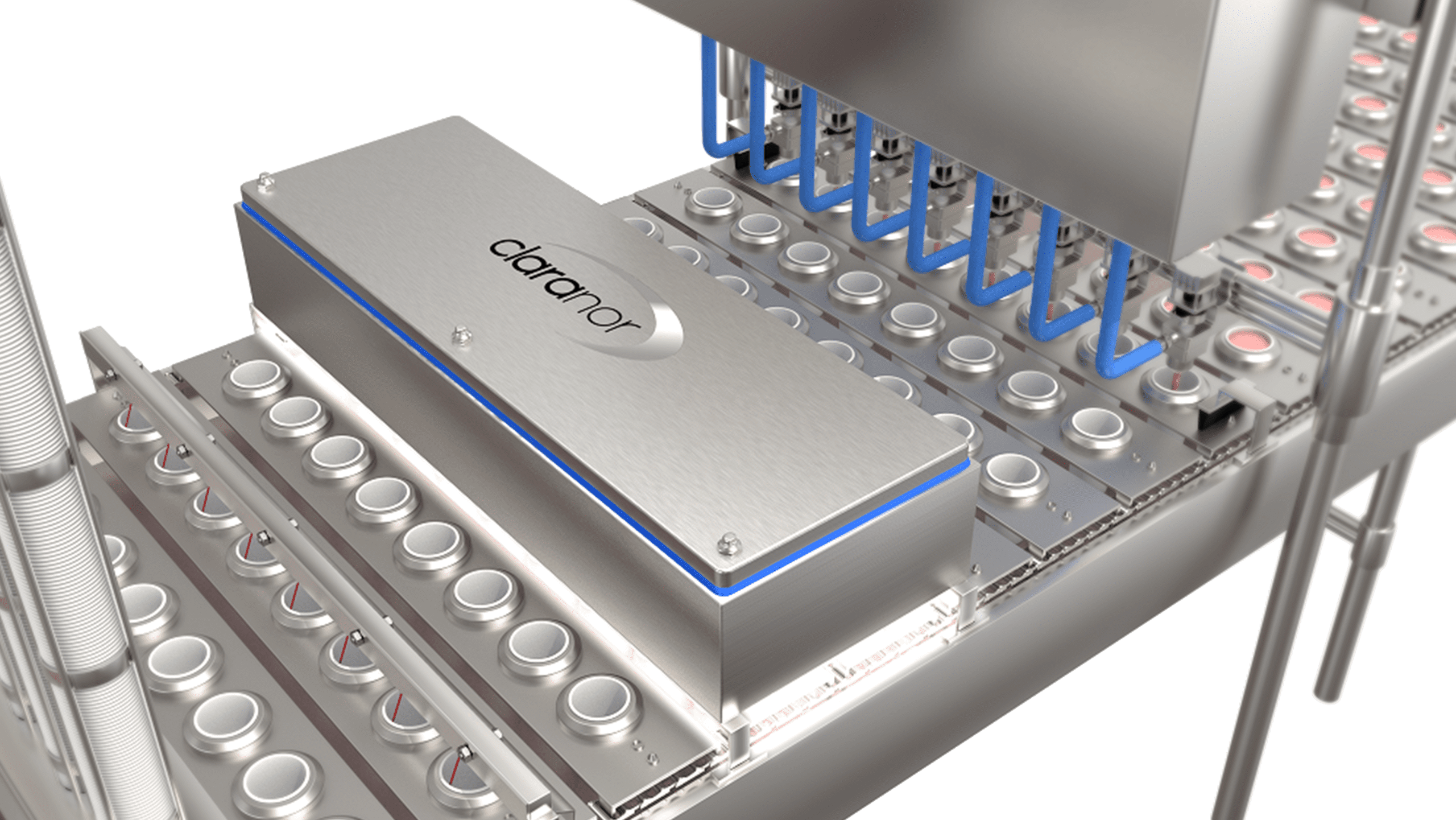

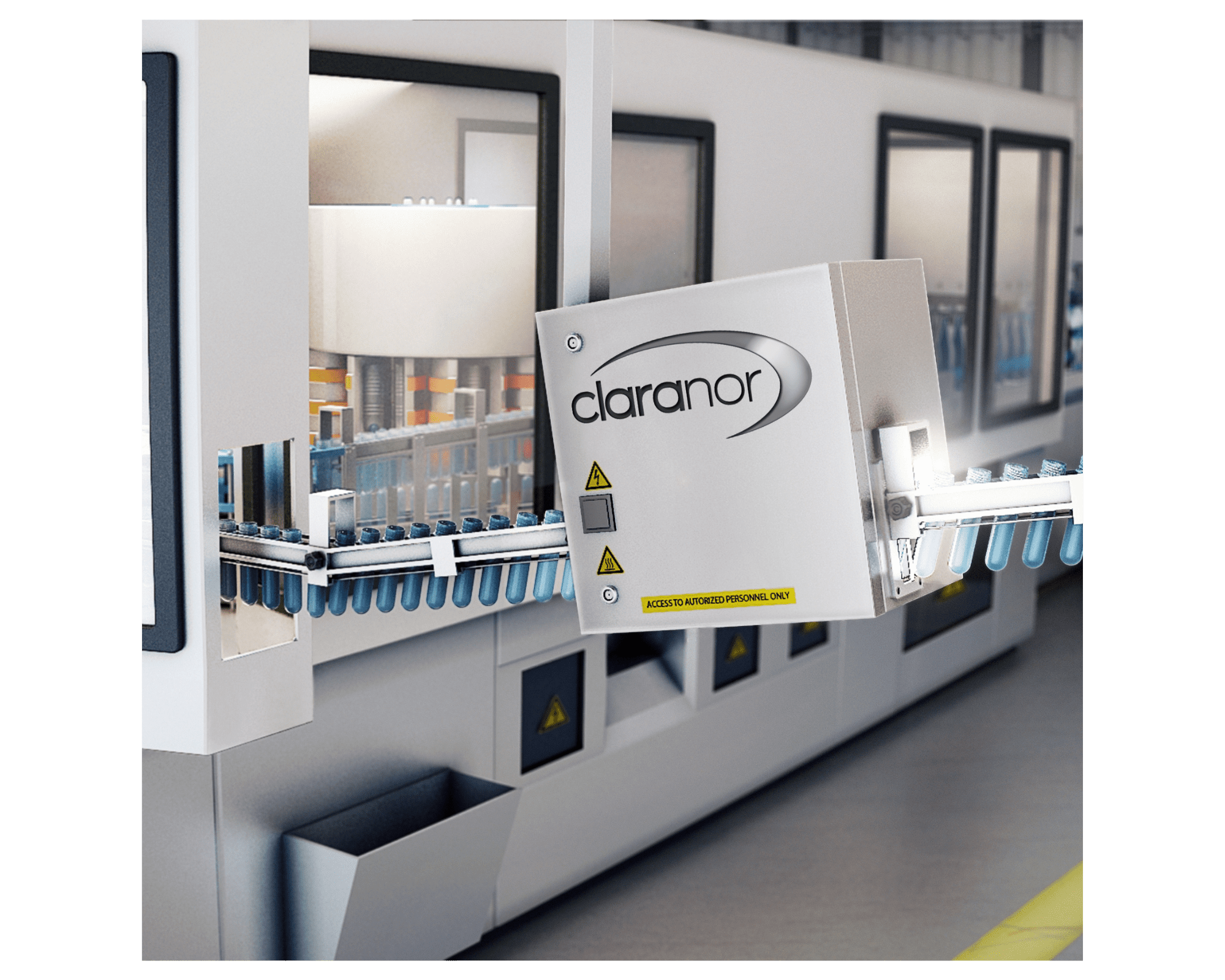

Cup & Lid decontamination

Respect the integrity of the lid

& sealing properties

Claranor decontaminates the lids (all materials and formats) by an instant process, up to 60 strokes / minutes.

Non thermal process, it respects the sealing properties and the integrity of the lid : no deterioration, no shricking effect. Moreover, there is no risk of chemical residue.

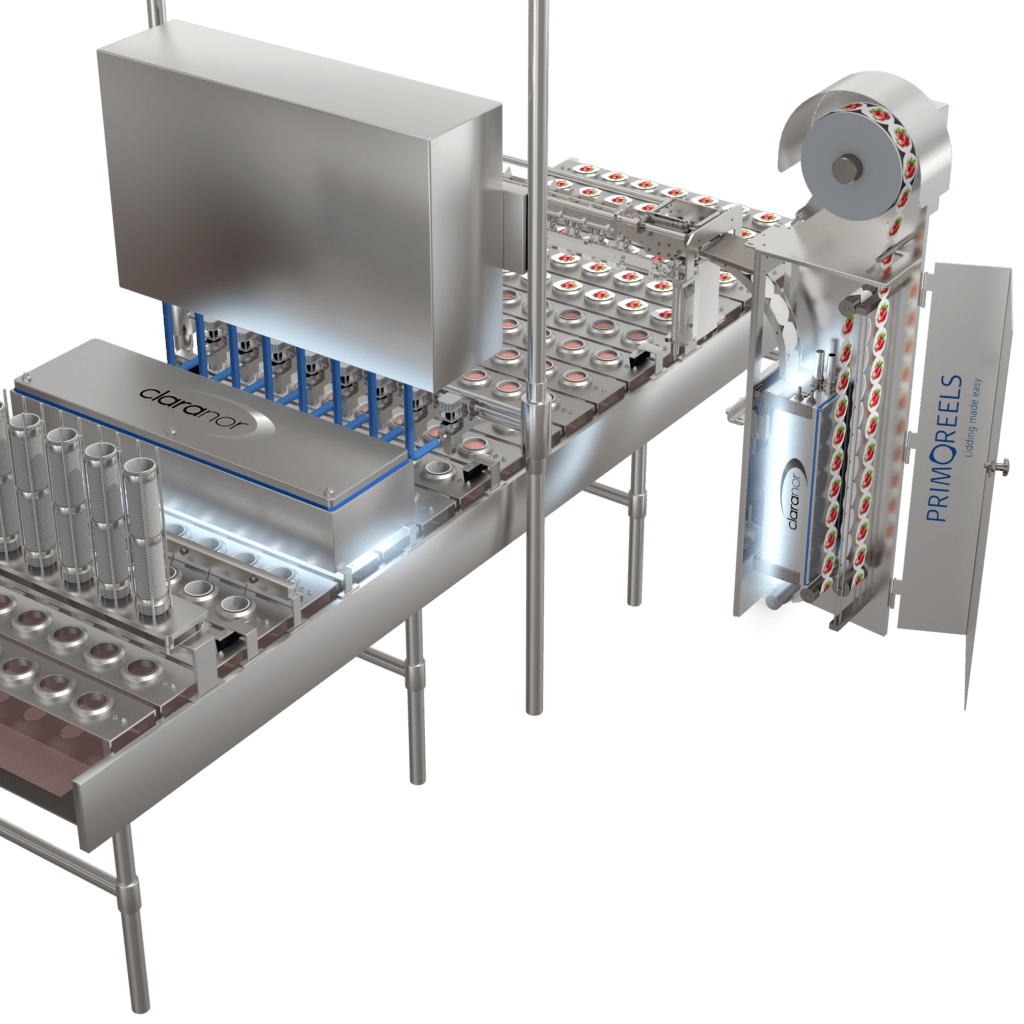

Enhance productivity and hygiene with Primoreels!

Primoreels and Claranor join forces to offer an easy and clean lidding system that allows energy and packaging savings. Moreover, it also makes chemical free decontamination safer and easier.

The reel principle allows the use of very thin films and the patended layout reduces film consumption.

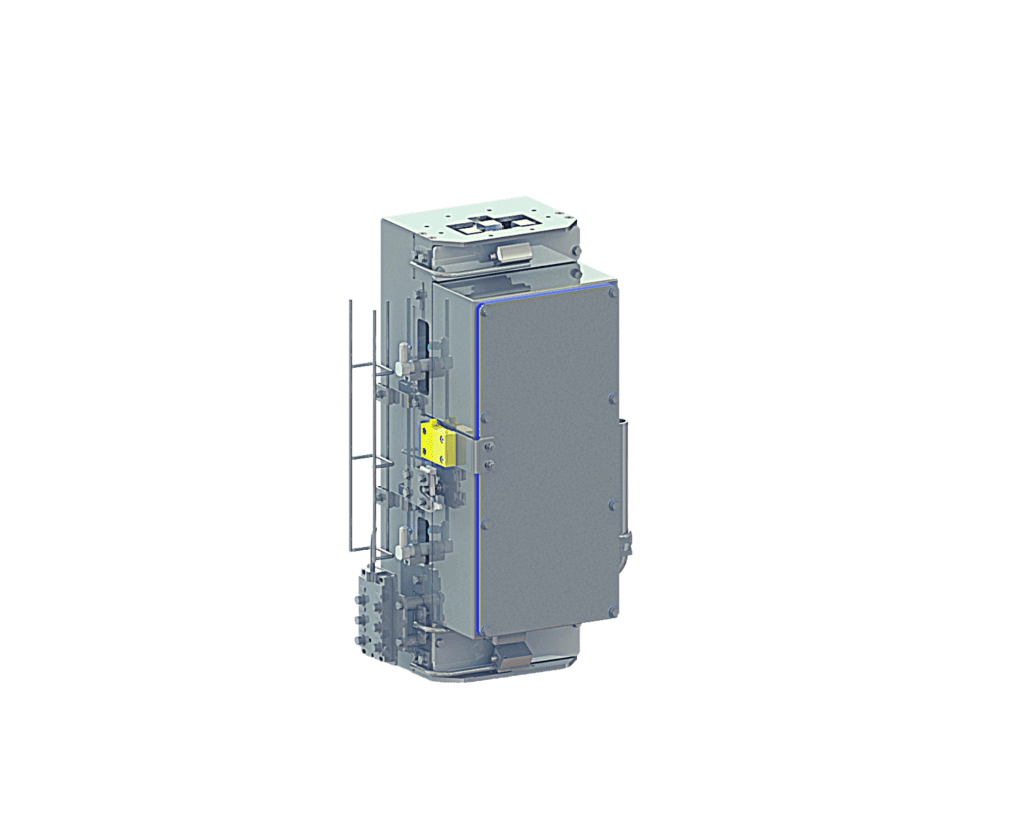

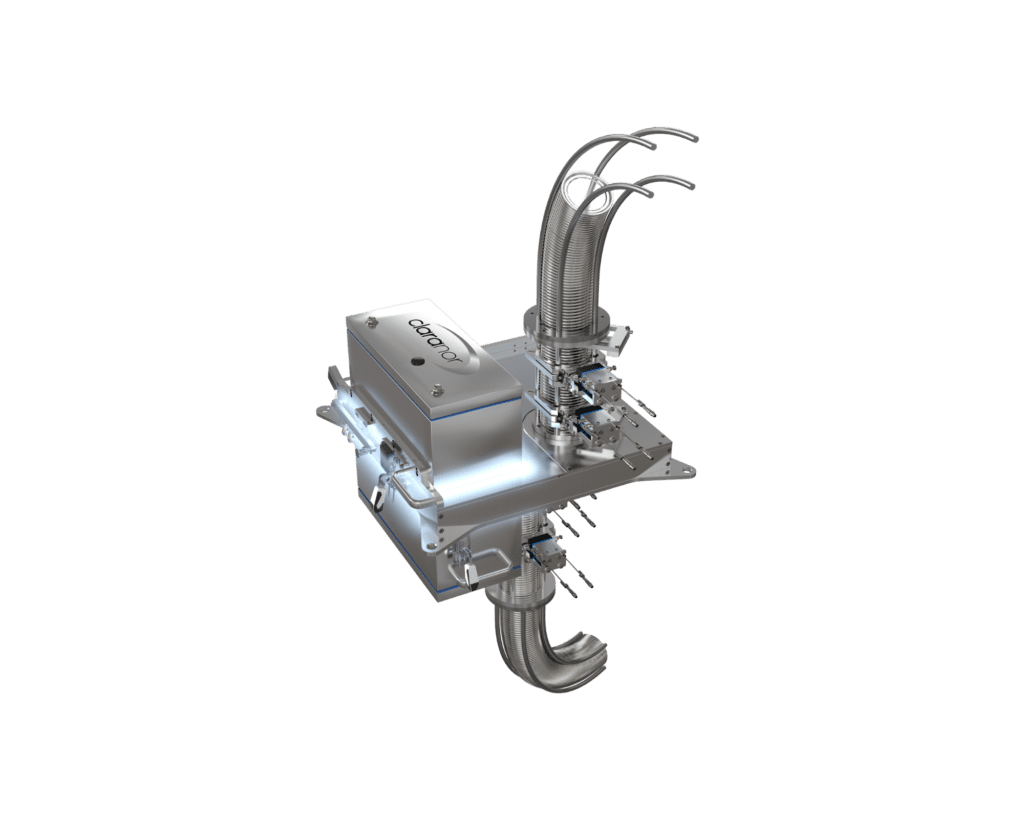

Cap & Preform decontamination

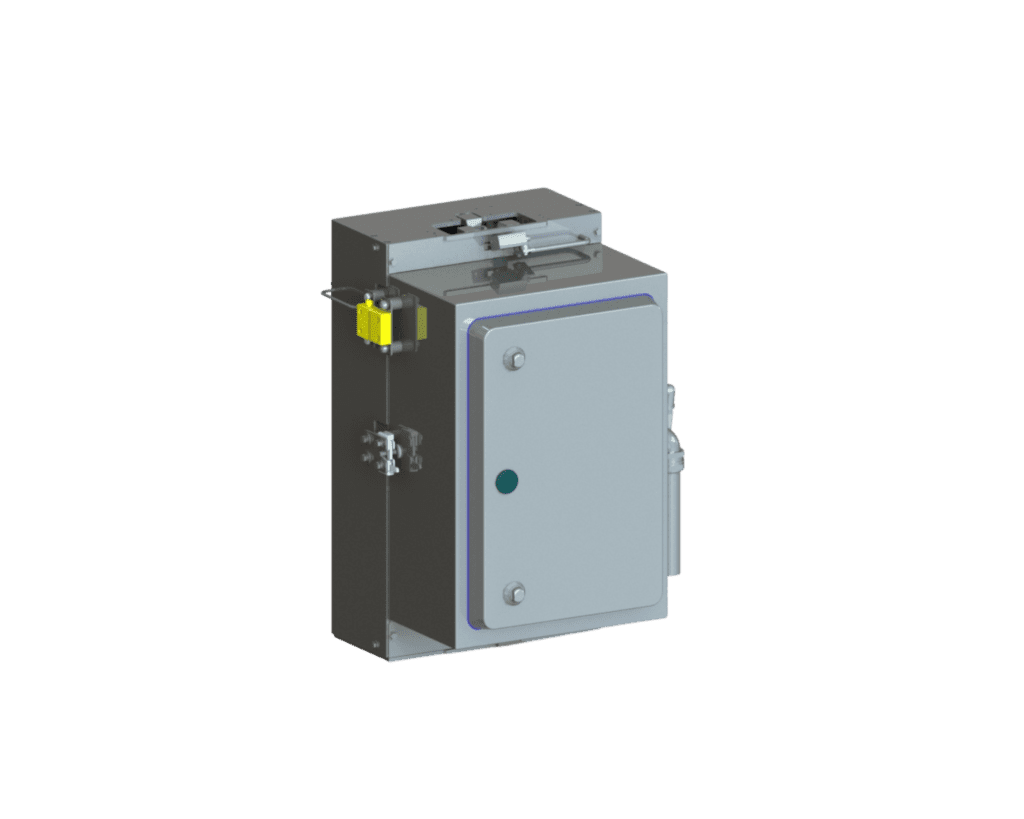

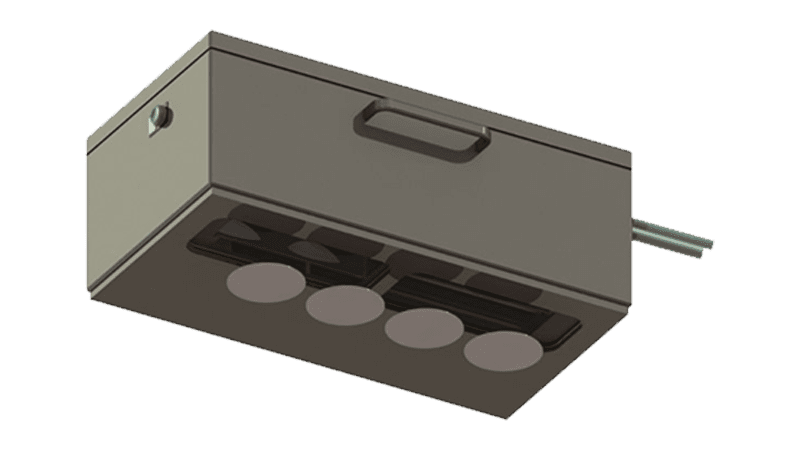

Can decontamination

Craft Beer is often unpasteurized, making it more vulnerable to microbiological contamination.

Therefore, Claranor has designed a new equipment achieving a Log 3 reduction (yeast and mold, bacteria) and allowing the decontamination of can and lid to prevent this risk.